3DLIGHTSLAB

3DCP FOR STRESS BASED HORIZONTAL STRUCTURES

Project ID

PROJECT BY

PARTNERS

YEAR

SITE

TYPE

TEAM

ROLE

SDU.CREATE, Led by Assoc. Prof. Dr. Roberto Naboni

Hyperion Robotics, Weber Saint Gobain

2024

Odense, South Denmark

Research Project

Luca Breseghello, Hamed Hajikarimian,

Daniele Florenzano, Roberto Naboni

Fabrication and Construction,

Stuctural Testing, Design and Fabrication of Supports

Project Description

3DLightSlab aims at revolutionizing construction practices through 3D Concrete Printing (3DCP). With a primary goal of reducing CO2 emissions in the built environment, our study employs stress-based design principles to create load-bearing slabs with high sustainable potential. These slabs feature isostatic ribs that adapt to various shapes, support arrangements, and load conditions, optimizing rib layout and material efficiency. A comprehensive case study showcases a load-bearing slab supported by two columns, demonstrating its capacity to withstand combined loads. Our streamlined pipeline incorporates Finite Element Analysis (FEA) to fine-tune rib dimensions and density, ensuring structural integrity that meets Eurocode standards for serviceability. The fabrication process employs rapid material deposition methods, and bending tests, simulated through a shell-based approach, affirm the slabs' ability to meet design loads. The design of 3DLightSlab, its successful fabrication, and structural testing prove the potential of 3DCP to overcome the manufacturing limitations that have limited the widespread adoption of isostatic ribbed slabs. Coupling the principles of the architectural precedents from Pierluigi Nervi and Hans-Dieter Hecker with computational design and the additive nature of 3DCP, a new aesthetic emerges for structurally-efficient horizontal structures of a reduced environmental impact.

TOOLPATH DESIGN

The toolpath design of the structure derives from a structurally optimised configuration of ribs selected through a multiobjective optimisation algorithm. The toolpath follows an alternation between printing trajectories and travel motions.

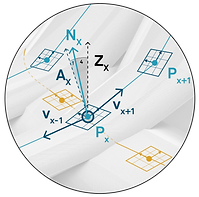

TARGET ORIENTATION

Each point describing the geometry of the toolpath corresponds to a robot motion target, and it is described by a plane which follows the non-planar geometry using reorientation.

REINFORCEMENT STRATEGY

The 3D printed slab is integrated with three layers of reinforcements: a first 4mm steel mesh in the rectangular base of the structure, a bottom layer of 8mm rebars in the area of the two supports, and a top layer reinforcement of 6mm cables in stainless steel.

STRUCTURAL TESTING

The slab design has undergone thorough structural simulations through FEA analysis and has also been tested under standard loading conditions according to the serviceability limit state of the Eurocode, performing within the standards.